[car home Brand History] In recent years, Wuling Automobile has maintained its position as the "leader" in the field of mini-cars, or in the cooperation of "SAIC+GM+Wuling", its development momentum is so strong. However, before Wuling transformed into a mini-car, its arduous development course was little known. From the founding of New China to the present, Wuling Automobile has been accompanying the social and economic development of China. From Liuzhou Power Machinery Factory to the transformation of tractor production, from "specialized with miscellaneous products" to the development of mini-cars, the development of "Wuling" is accompanied by the continuous social and economic progress in China, and also bears witness to the deep imprint of the history of New China along the way. Today, let’s review this car brand from New China.

Formerly known as Liuzhou power machinery factory

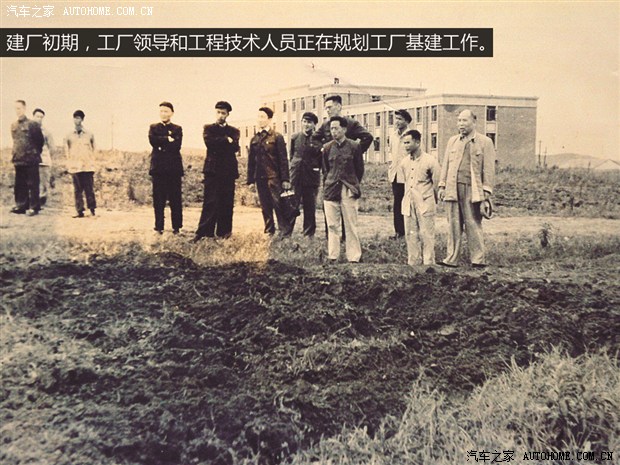

At the beginning of 1958, under the guidance of the general line put forward by the Central Committee, "Make full efforts, strive for the upper reaches, and build socialism quickly, well and economically", Guangxi Zhuang Autonomous Region decided to expand Liuzhou Machinery Factory into the main production base of Guangxi power machinery, mainly for large marine diesel engines. On October 28th of that year, the new plant of Liuzhou Power Machinery Factory, the predecessor of Wuling, officially broke ground, marking the beginning of the company’s first venture.

Put into operation a bumper harvest tractor.

Liuzhou Power Machinery Factory is separated from Liuzhou Machinery Factory (hereinafter referred to as "Liuji"). Power machinery is engaged here, and military supplies are engaged in the parent factory there. But in 1959, during the difficult economic period, the country basically had no demand for ship production, so Liuzhou Power Machinery Factory could not develop well. In response to Chairman Mao’s call of "realizing agricultural mechanization nationwide in 1980", Liuzhou Power Machinery Factory began to switch production and trial-produce tractors in 1961-1962.

In September 1964, the tractor was successfully trial-produced, and it is planned to produce 300 tractors annually. In 1965, Fengshou tractor was listed as a national standard product through expert appraisal. Wuling people in the initial stage left many stories of hard work and self-improvement.

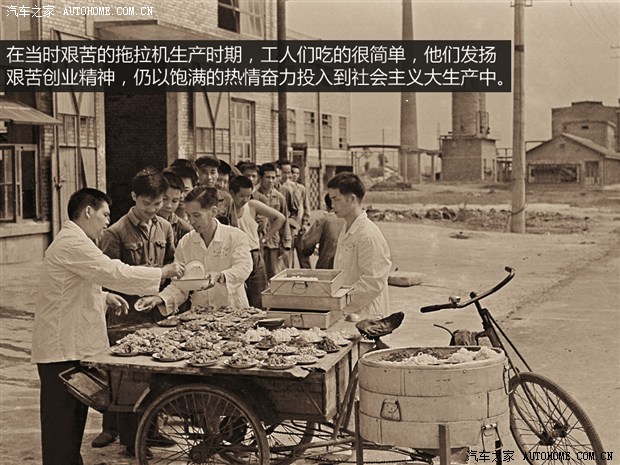

At that time, it coincided with the Cultural Revolution, but Wuling people never stopped production, stayed on the crude production line, ate simple food and focused on the production and research and development of tractors.

The output and quality of tractors are constantly improving, and they are deeply loved by farmers. In the mid-1970s, Liuzhou Tractor Factory increased by 40% every year and doubled in two years, with an annual output of 5,000 vehicles. From a local small tractor factory, Liuzhou Tractor Factory became one of the eight largest tractor factories in China. Liuzhou tractor factory has turned losses into profits, which seems to be the most prosperous time, but the problem has come out.

Maintain survival by "miscellaneous support and specialization"

At that time, the sales of tractor factory belonged to the planned economy, that is, the state gave a plan, while tractor factory ignored marketing. The tractors produced will enter the warehouse of the Agricultural Machinery Bureau as soon as they get off the line, and the Agricultural Machinery Bureau will "pay the bill". At the end of 1978, the production of tractors reached its peak. In the same year, the Third Plenary Session of the Eleventh Central Committee was held, the country carried out system reform, and with the policy of "land contract", industrial products were no longer underwritten. In 1980, the factory had a backlog of 1713 tractors, which made a loss for the whole year and faced a survival dilemma.

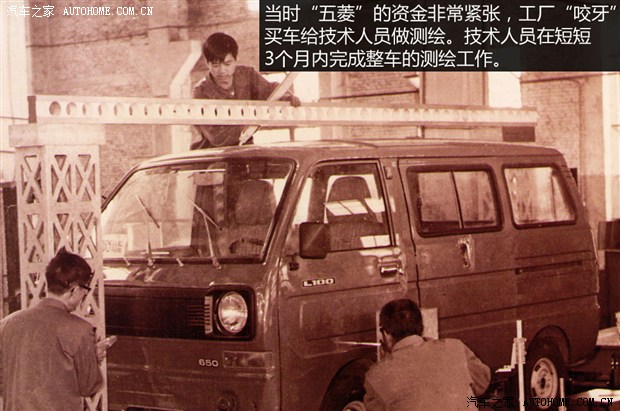

In order to survive and develop, the broad masses of cadres and comrades seek sewing machines, looms and other products to do, and they also realize that it is impossible to cling to the tractor as a single product. This will not only keep the tractor, but also make it difficult for the factory to survive, so we must make up our minds to adjust the production. At the beginning of 1980, the Military Industry Bureau of the Central Ministry of Agricultural Machinery introduced a Japanese Mitsubishi pickup truck and organized relevant domestic manufacturers to study and tackle key problems, but Liuzhou tractor factory was not included here. After learning the relevant news, Liuzhou Tractor Factory resisted various pressures, introduced a Japanese mini-car and started its own research.

In view of the fact that some light industrial and civil products sold well at that time and there was a lack of mini-cars in China’s automobile industry, the factory decided to switch to multifunctional sewing machines and 1515 automatic shuttle-changing cotton looms to survive, and began to develop mini-cars on the one hand. These representative slogans, such as "specialized in miscellaneous services, no loss, no profit" and "standing firm and punching fists", vividly outlined the living conditions of Wuling at that time.

The development idea of "specialized with miscellaneous products" not only eased the survival dilemma faced by the factory, but also created favorable conditions for the development of mini-cars in the same period.

Embark on the road of converting to mini-cars

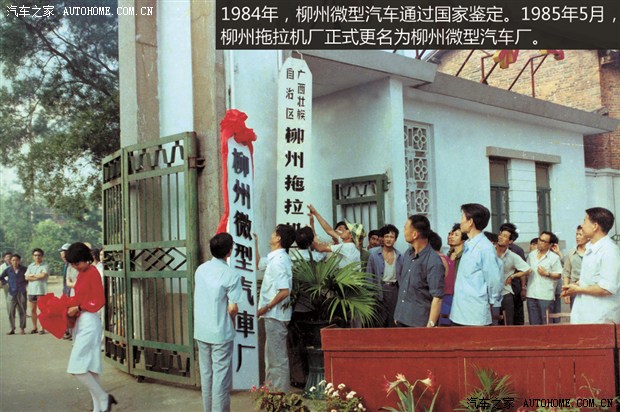

In January, 1982, LZ110, the first minivan developed by the factory by manual tapping and copying, was successfully trial-produced, achieving a zero breakthrough in the field of minivan manufacturing. On September 13th, the People’s Government of Guangxi Zhuang Autonomous Region issued the Notice on the Joint Construction of Mini-cars by Liu Tuo and Liu Ji, and decided that Liu Tuo would switch to mini-cars. On April 1st, 1983, the State Planning Commission and the Economic Commission issued the document No.425 (1983) Notice on Doing a Good Job in Fixed-point Minicars, and the factory was designated by the State Planning Commission and the Ministry of Machinery Industry as one of the four designated mini-car manufacturers in China. In October 1984, the "Wuling" LZ110 minivan produced by Liuzhou Tractor Factory passed the national technical appraisal. More than 2,300 vehicles were put on the market that year, which was very popular with users.

In 1985, the factory actually produced 4,224 cars with a total industrial output value of 73.23 million yuan, exceeding the five-year adjustment of "3,000 small trucks with a total industrial output value of 60 million yuan". Also in this year, Liuzhou Tractor Factory was officially renamed Liuzhou Mini-car Factory, successfully transforming mini-cars.

Speaking of the logo of Wuling, at first, the mini-car used the "W" logo of the "Wanjia" brand sewing machine produced by the company, and later changed it to a gem logo. One day, a young college student named Wei Hongwen re-created the logo of Wuling in use according to some reflections at that time. The newly designed logo is composed of five diamonds in the shape of "W", which is consistent with the pinyin letters of "Five". The overall design is simple and generous, giving people a strong impression of "taking off and flying". At that time, the leading group in the factory attached great importance to it and held a meeting to discuss it repeatedly, and finally unanimously agreed to this idea. In 1987, when the Z110OVH van rolled off the assembly line, the new Wuling logo was officially registered and activated, and it has been used ever since.

After the transformation of mini-cars, "Wuling" actively raised money and technology from all walks of life to continuously improve the company’s manufacturing level and product quality. At the same time, three phases of large-scale technical transformation and quality improvement were carried out around the four major processes of automobile production: stamping, welding, painting and final assembly.

At the same time, Liuzhou mini-car factory began to actively explore the way out of the country. In 1990, the first batch of 15 mini-cars were exported to Thailand, achieving a zero breakthrough in foreign exports.

In 1992, the annual output of Liuzhou mini-cars ranked second in the same industry and 13th among 40 auto factories with an annual output of more than 10,000 vehicles in China. Thus, Liuzhou mini-car factory has occupied a considerable position in the national auto industry. Moreover, in terms of quality, since 1987, Liuzhou mini-cars have reached the first-class product in every inspection, and in 1990, the products were also listed as "inspection-free products". For example, the main performance indexes of LZ110P truck have reached the international advanced level of similar products in 1980s, and it has been rated as "China recognized brand-name product" by users.

Through foreign cooperation and the third-phase technical transformation, Liuzhou Mini-car Factory has a modern production line, with the continuous improvement of manufacturing capacity, management level, production efficiency and product quality, the product line is gradually enriched and the production capacity is gradually expanded. In 1995, its annual production and sales reached 50,000 vehicles, and the scale benefit began to show, and it increased by nearly 20% every year. In the same year, Wuling automobile entered the Tibet market, the roof of the world.

Established liuzhou wuling Automobile Co., Ltd.

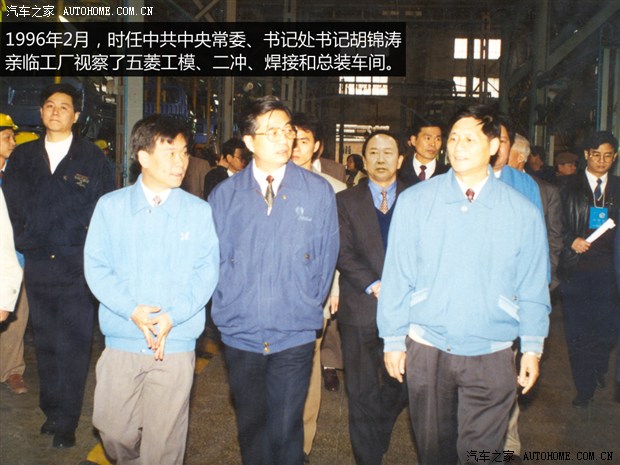

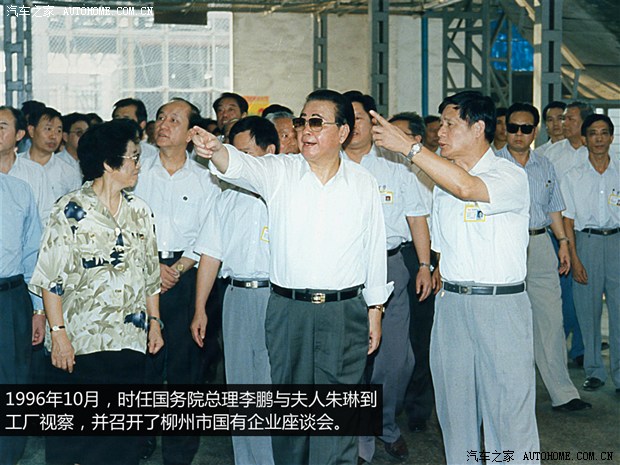

On February 28th, 1996, liuzhou wuling Automobile Co., Ltd. was established. During this period, many national leaders visited the factory for inspection and guidance.

On July 8, 1996, Wuling Automobile finally signed a technical assistance contract with Daihatsu Automobile Co., Ltd. of Japan after many investigations and textual research. In the same year, the first batch of 10 LZW6370A jointly developed by the two parties rolled off the production line, and the car made its first public appearance at the "China Wuling Automobile’ 97 Beijing Press Conference" held at Diaoyutai State Guesthouse on March 16th, 1997.

Because the car body is lowered and the front of the car is moved forward, the whole appearance changes from the past, and it looks smooth and smooth, like a bullet. The car uses a Japanese Daihatsu 1.3L inline four-cylinder naturally aspirated engine with a maximum power of 54 kW. In addition, the angles of the three rows of seats can be adjusted, and the rear seats can be folded to increase the loading space, which is an ideal model for public and domestic use at that time.

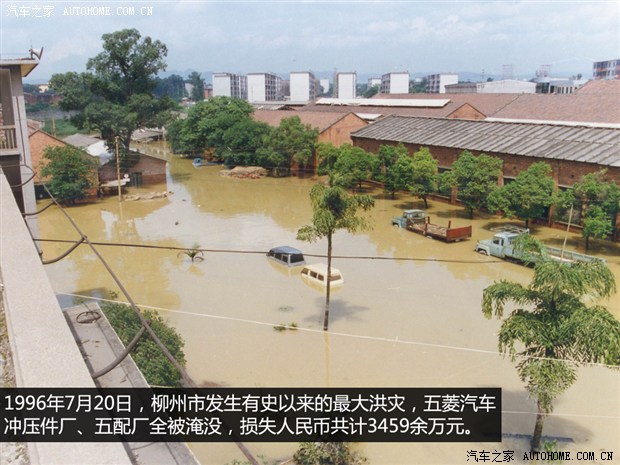

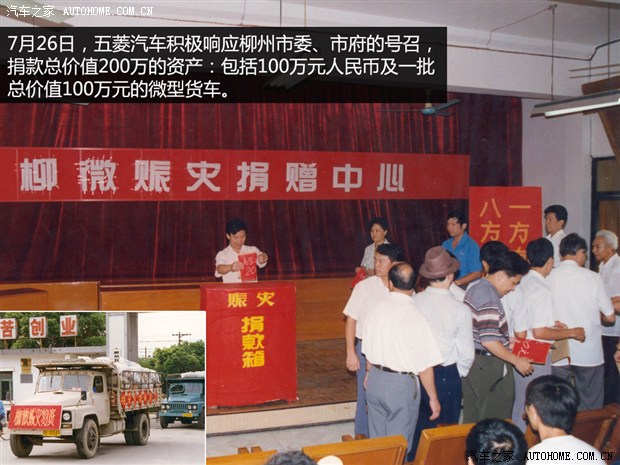

While people were immersed in joy, a sudden disaster happened. On July 20, 1996, the biggest flood disaster occurred in Liuzhou, Guangxi, and the stamping parts factory and the fifth distribution factory of Wuling automobile were all submerged, resulting in serious losses. However, Wuling people are not silent in the negative and grief. They are united in their efforts to overcome difficulties and actively participate in the restoration and construction of the factory and production. At the same time, on July 26, Wuling people carried forward the spirit of "one party is in trouble and all directions support", did their part, actively responded to the call of Liuzhou Municipal Party Committee and Municipal Government, and held a donation activity of relief materials.

Seeking a way out in the predicament of developing Wuling automobile through joint venture

In December 1998, the production and sales volume of Wuling automobile reached 100 thousand, ranking first in the domestic mini-car industry; On July 13th, 1999, liuzhou wuling Automobile Co., Ltd. was established.

On August 23rd of the same year, the 500,000th Wuling automobile rolled off the assembly line. But behind this glamorous figure, there is a turbulent torrent of competition in the micro-car market. In June, 1999, the market share has dropped from more than 20% to 15%, and Wuling is facing challenges again. With the rapid development of the enterprise, the problem of extensive management has emerged, which has also brought thinking to the management. At that time, it was obvious that the stamina was insufficient, and whether it was funds, management or technology, it was inadequate. At this time, the reform of state-owned enterprises has developed into a new stage of enterprise reorganization and the introduction of foreign capital and technology, and the urban government and factory leaders have also begun to work hard in this regard.

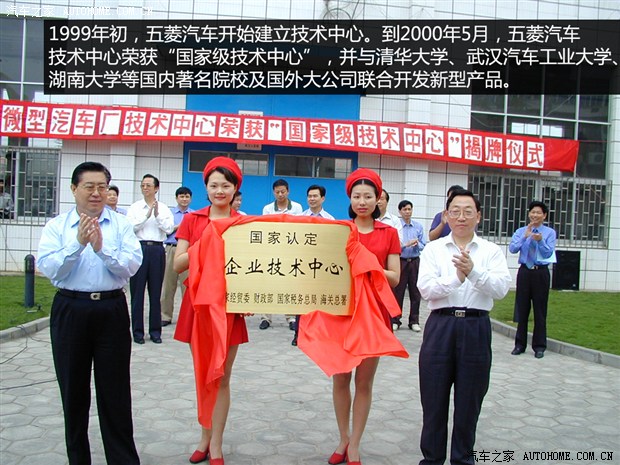

Under the severe situation, Wuling automobile decided to get rid of the simple extension and expand the reproduction mode, and carry out comprehensive reform and upgrading in management, quality and technology. In terms of quality control, it successfully passed the authoritative third-party certification of ISO9001 quality system in September, becoming the first domestic micro-car enterprise to pass this certification; In terms of technology upgrading, Wuling Automobile invested heavily in establishing a technology center, obtained a national-level technology center and an enterprise postdoctoral workstation, and began to take the road of independent research and development of integrated resources of "production, learning and research", which greatly enhanced the company’s research and development strength.

In 2000, Wuling Automobile continued to expand its export trade, and signed cooperation agreements with Indonesia and Syria in May and October.

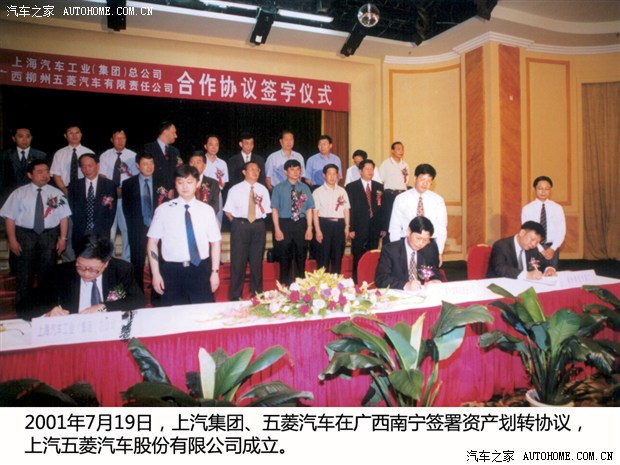

In the process of seeking foreign cooperation, Wuling Automobile has constantly seized cooperation opportunities and explored ways of cooperation. At that time, many domestic automobile factories had joint ventures with famous foreign automobile companies, and the situation was promising. Sichuan Changhe was a pioneer. So Wuling also intends to talk about joint venture with GM through "municipal government leading and enterprises cooperating". However, at that time, the central government stipulated that a foreign company could only engage in joint ventures with two domestic enterprises at most. At that time, GM already had two, one of which was SAIC. Only by joining SAIC first can we cooperate with GM as SAIC. In July, 2001, Wuling Automobile formed a strategic cooperation with SAIC in the form of allocation of assets from the core enterprise liuzhou wuling Automobile Co., Ltd., and achieved the first step of "expanding".

SAIC-GM-Wuling Automobile Co., Ltd. was established.

The year 2002 was a milestone for Wuling Automobile. In June, Wuling Automobile reached a cooperation with SAIC and General Motors of the United States, and established a tripartite joint venture-SAIC-GM-Wuling Automobile Co., Ltd. (SGMW for short). Wuling Automobile allocated its resource advantages to SAIC, and finally gave birth to SAIC-GM-Wuling Automobile Co., Ltd., which was formed by SAIC, GM and Wuling Automobile. ) and officially listed on November 18th of that year. At this point, Wuling Automobile has integrated the resources and advantages of SAIC and American General Motors in capital, technology and management, and stood at a brand-new starting point and entered a stage of rapid development.

In 2001, Wuling Light began research and development. However, after the prototype rolled off the assembly line, the company found that its body was too narrow and decided to widen the width of the body from 1.40 meters to 1.56 meters. In November 2002, Wuling Light went offline and was officially listed, but the response in the market was not satisfactory. This is related to the short development cycle and insufficient preparation. In addition, although there is no big problem with the new car just listed, there are many minor problems such as "running, dripping and leaking", such as burrs on the seat, poor sealing of the rubber strip, silent horn and oil leakage in the rear axle.

Faced with these problems, SAIC-GM-Wuling decided that it would rather not sell cars than solve these problems first. They specially invited experts from General Motors to improve product quality. After less than half a year’s efforts, all these minor problems have been solved. The time when the new car broke down for the first time has increased from less than 3,000 kilometers to more than 5,000 kilometers. The market feedback is also obvious. By June and July of 2003, the sales of Wuling Light had gone up.

So far, the classic model of Wuling Light has gone through more than ten years, and it is still a product that users pay attention to and rely on. In 2012, Forbes magazine selected the 12 best-selling cars in the world in 2011. In addition to Toyota Corolla and Hyundai Elantra ranked first and second, Wuling Light ranked third with global sales of 943,000 vehicles. It is also the only non-car product among all the models on the list, and the only brand originated from China. Just the year before, it was praised by Forbes as "THE MOST IMPORTANT CAR ON EARTH" (the most important car on earth).

After the joint venture, SAIC-GM-Wuling took the integration of excellent resources of shareholders and the integrated development of the three parties as the primary task, and formulated the development strategy of "one steering wheel, four wheels", which guided the joint venture company to integrate development through learning and collision, and continuously improved the company’s management, research and development, manufacturing, sales and service system.

A steering wheel, that is, the corporate culture of SAIC-GM-Wuling, includes its purpose (to become a leading domestic and internationally competitive automobile company for mini-cars), values (customer satisfaction, teamwork, learning and innovation, honesty and trustworthiness, high efficiency and pragmatism) and mission (to gather resources from three parties, highlight the advantages of low cost and high value, form the unique core competitiveness of SAIC-GM-Wuling, and realize the expectations of shareholders, customers and employees). The four wheels refer to excellent resource integration ability, human resources, technology and management innovation and capital respectively.

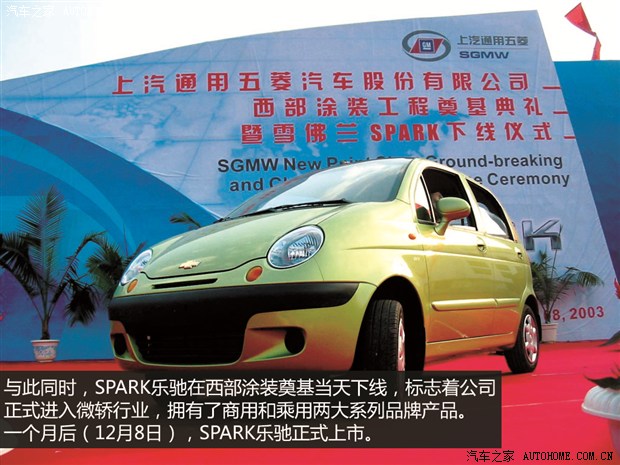

On November 8, 2003, SAIC-GM-Wuling laid a grand foundation stone for the new painting workshop in the west, and Chevrolet SPARK Le Chi also rolled off the assembly line on the same day. On December 8th, SPARK Le Chi 0.8L displacement vehicle was officially launched. In addition, in order to meet the further market demand, Chevrolet SPARK Le Chi 1.0L displacement model was launched on November 30th, 2004.

On June 1st, 2005, the foundation stone was laid for Liuzhou Engine Factory with an investment of over 2 billion yuan, which is also the largest investment project after the tripartite joint venture. This international advanced and domestic first-class engine production base has provided strong support for the rapid development of SAIC-GM-Wuling, which is of great significance to comprehensively enhance market competitiveness.

On June 2, 2005, SAIC-GM-Wuling and Yizhong (Qingdao) Transport Vehicle Manufacturing Co., Ltd. held an asset transfer signing ceremony in Qingdao, which indicated that SAIC-GM-Wuling had set up a camp in Qingdao and established a production base directly facing the northern market.

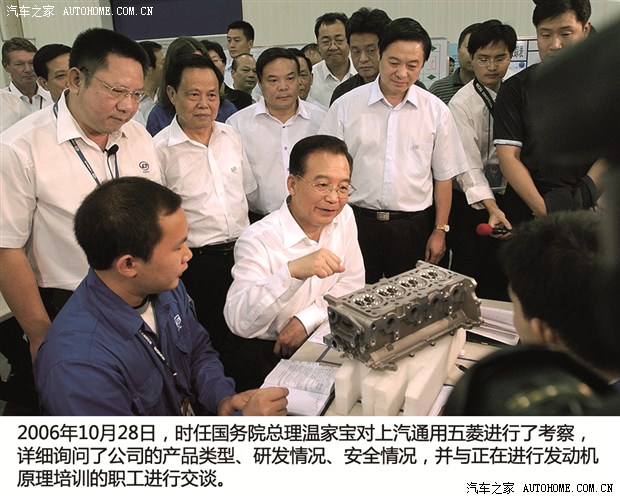

On January 1st, 2006, the annual production and sales volume of SAIC-GM-Wuling exceeded 460,000 vehicles, regaining the first position in the micro-car industry (from 2003 to 2006, the annual production and sales volume were 180,000 vehicles, 235,000 vehicles, 335,000 vehicles and 460,000 vehicles respectively, and the market share rose from 18.87% to 38%). In May of the same year, SAIC-GM-Wuling held a long-term cooperation signing ceremony with Hunan University, creating a localized and shared independent research and development model; In September, SAIC-GM-Wuling also held the unveiling ceremony of "Shanghai Jiaotong University-SAIC-GM-Wuling Modern Body Technology Joint Research Center". In November, SAIC-GM-Wuling made its debut at the Beijing Auto Show with the theme of "Winning the Future" and products such as Wuling Light Extended Model, SPARK Le Chi Concept Car and Wuling Hongtu. This is also the first time that SAIC-GM-Wuling has independently participated in the international auto show since the tripartite joint venture. On November 19th, SAIC-GM-Wuling signed the "Strategic Cooperation Agreement on Independent Innovation" with China Automotive Technology Research Center, which indicates that SAIC-GM-Wuling has taken another step in the journey of independent innovation in sharing resources.

B series engine off the assembly line

The B-series engines put into production by SAIC-GM-Wuling are designed with general global engine technology, developed by SGMW Technology Center, and independently manufactured according to the characteristics of the domestic market. B series engines are characterized by low cost, low fuel consumption and high power. The biggest technical highlight is that the lifting power is more than 50kW/L. In addition, the 16-valve, double overhead camshaft and multipoint injection make the fuel fully burn and achieve the best economic effect.

On March 31, 2008, with the completion and commissioning of the new factory of Qingdao Branch with a vehicle capacity of 300,000, it marked the basic formation of the north-south layout of SAIC-GM-Wuling manufacturing system, further consolidating its leading position in the field of mini-cars.

Following the listing of Wuling Hongtu, at the Beijing Auto Show in April 2008, SAIC-GM-Wuling officially released wuling glory, which was independently developed and equipped with B-series high-power engines, thus creating an era of "big micro-passengers". On June 3rd of the same year, wuling glory was officially listed in Qingdao and began to sell to the outside world. Now, after several years, wuling glory has become a well-known micro-surface product. The large size (length/width/height are 4135/1660/1870mm respectively) brings large space, and the wheelbase is 2700 mm.

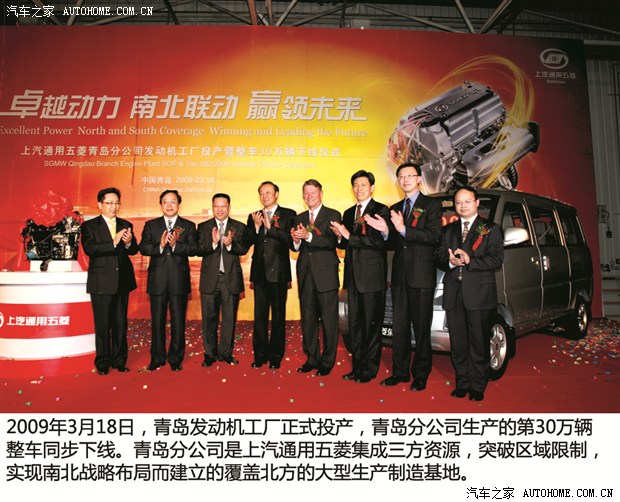

In March, 2009, Qingdao Engine Factory was officially put into operation. Qingdao Branch has two manufacturing plants, namely vehicle and engine, with an area of 461,000 square meters at the beginning of listing to 520,000 square meters now. The product line has expanded from the original Wuling Xingwang single product to a series of products including wuling glory and PN series and single and double-row trucks.

On December 18th, 2009, the millionth mini-car of SAIC-GM-Wuling-the light of the new Wuling rolled off the assembly line in the west, and SAIC-GM-Wuling became the first single automobile enterprise in China with annual production and sales exceeding one million vehicles.

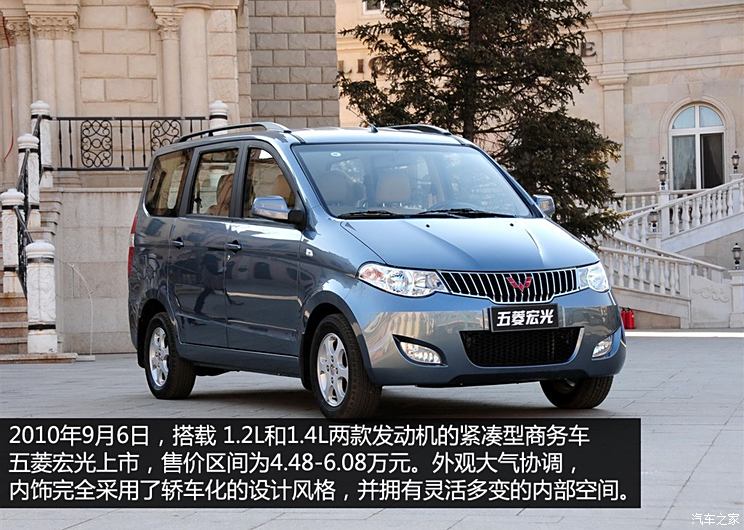

At the Beijing Auto Show on April 23rd, 2010, SAIC-GM-Wuling released a brand-new compact commercial vehicle-Wuling Hongguang, which was the first to open a brand-new market segment of domestic compact commercial vehicles. This well-known compact business product was launched on September 6th. It has created a new world in the large-scale commercial vehicle market and subverted people’s traditional impression of commercial vehicles.

Wuling Hongguang’s appearance design and practicality are beyond ordinary micro-surface products, and it has high cost performance for joint venture MPV and commercial vehicles. Moreover, the interior is completely close to sedan, and the advantages of the car are large space and flexible seats. For users in the second and third tier markets, they pay attention to practicality, have no high brand awareness and are sensitive to cost performance. The listing of Wuling Hongguang meets the various needs of local users for business and home use and has attracted high attention.

Passenger car independent brand "Baojun" released

On July 18th of the same year, SAIC-GM-Wuling officially released a brand-new independent brand of passenger cars-"Baojun" in Shanghai, which marked that SAIC-GM-Wuling began to fully enter the field of passenger cars. At the press conference, SAIC-GM-Wuling also revealed that the first product of Baojun will be a compact car, and other passenger cars such as SUV and MPV will also be developed.

On August 9th, 2011, this Baojun 630 with the logo of SAIC-GM-Wuling new passenger car finally kicked off the national tour listing in Chengdu under the background of "long-awaited". It was equipped with a 1.5L naturally aspirated engine and a 5MT manual gearbox, and the price range was 6.28-73,800 yuan. Its 1.5L automatic transmission model and 1.8L model were also launched in April and September 2012, respectively.

With the continuous enrichment of products, SAIC-GM-Wuling has also begun to increase its share and influence in the passenger car market through Baojun Automobile. In the "2012 China Automobile Industry Customer Satisfaction" survey, Baojun 630 won the first place in the 50,000-80,000 yuan model for its superior cost performance, good quality and reputation.

On July 10th, 2012, wuling glory put on a Chevrolet gold bow tie (Chevrolet MOVE) and officially landed in the Egyptian passenger car market. For the first time, SAIC-GM-Wuling realized the mass assembly and production of its own products outside China in the form of parts export.

On August 15th of the same year, Chevrolet Le Chi turned into Baojun Le Chi and officially joined Baojun brand camp, becoming Baojun’s first A00-class sedan. After the rebranding, Baojun Le Chi declined in brand appeal, but its configuration was adjusted, which greatly increased its cost performance.

Wuling Hongguang S and wuling glory S are listed.

After Wuling Hongguang, a compact commercial vehicle product with a monthly sales volume of about 30,000 units, SAIC-GM-Wuling pursued victory and launched Wuling Hongguang S (video test: the world’s first monthly sales original test drive Wuling Hongguang S) on August 6, 2013. On the basis of Wuling Hongguang, the car has increased its body size, replaced with a 1.5L engine and enriched its configuration, thus enhancing its freshness and competitiveness. Due to the good performance of Wuling Hongguang market, Wuling Hongguang S attracted wide public attention when it was not listed. After listing, Wuling Hongguang S will be sold together with Wuling Hongguang, and compete with Changan Ounuo and Dongfeng Xiaokang scenery.

Just like Wuling Hongguang S, on November 22nd, 2013, wuling glory S was officially listed and entered the public eye. Compared with wuling glory, it has been completely upgraded in appearance and interior. The two are also sold under the same roof.

By the end of 2013, SAIC-GM-Wuling has owned two automobile brands, Wuling Hongguang, wuling glory, Wuling Zhiguang, Baojun 630 and Le Chi, and has three manufacturing bases, namely, Liuzhou Hexi Headquarters, Liudong Baojun and Qingdao. At present, its annual production capacity reaches 1.31 million vehicles and 1.05 million engines. Today, SAIC-GM-Wuling has been a "million" automobile enterprise in China for five consecutive years. When it becomes the leading car enterprise in the commercial vehicle market and gets a wider user base, it is gradually forging ahead in the field of passenger cars.

"Wuling" began its development process from the mass production movement of "building socialism" in the early days of the founding of New China. During this period, I experienced hard times, encountered difficult pressures, and completed three major transformations with the social and economic development and market demand in China. Nowadays, SAIC-GM-Wuling, which is signed by Wuling Automobile, SAIC and General Motors of the United States, has made remarkable achievements and good development momentum in the fields of commercial vehicles and passenger cars. We also expect SAIC-GM-Wuling to continue to develop rapidly and fulfill its promise to develop its own SUV and MPV models. (Text/Figure car home Wang Liang)

关于作者