[Gearbox Technology] In the current China market, consumers often regard whether to use it as a standard to judge the technical maturity of a car. Although there are still many "problems" to be solved, such as gear shifting frustration and inactive downshift, it is a big trend that more and more China brand vehicles are equipped with dual clutch gearboxes. With the listing of, the latest set of powertrain 1.4t+6 DCT has also come to us. So what about this 6-speed dual-clutch gearbox? Let’s take it apart to see what’s special about it.

● Why are more and more China brands using dual clutch?

When it comes to CVT, many consumers’ reaction is definitely that Japanese brand car companies prefer to use it. When it comes to AT, everyone’s reaction may be that American car companies prefer it. As for DCT dual-clutch gearbox, they will think of European brands. However, among so many types of gearboxes, why are more and more China car companies starting to use DCT dual-clutch gearboxes? This is about to start with the story behind it.

In 2008, led by the National Development and Reform Commission, China Development Alliance Investment Co., Ltd. was jointly established with nine China brand car companies, including SAIC and Bogwarner. Then China Development Alliance Investment Co., Ltd. and Bogwarner United Transmission System Co., Ltd. were formed, and the two parties held 34: 66 shares to jointly develop DCT dual-clutch gearbox. Since then, China automobile enterprises have started the road of independent research and development of dual-clutch gearbox. It can be said that the development of dual-clutch gearbox is an act at the national level, just like the electric vehicles that are vigorously developed now, and it is a "overtaking in corners" policy formulated by relevant departments after careful consideration.

Although Borgwarner United Transmission System Co., Ltd. was established, which formed an alliance at the company level, at the technical level, each company still formed its own alliance and established its own research and development direction and mode, so there was no such situation that a gearbox produced by Borgwarner United Transmission System Co., Ltd. was mounted on nine China brand models. So what role does Borgwarner play in it? To understand this mATter, we must first look at some background knowledge about CVT, AT and DCT.

◆ CVT transmission steel belt monopolized by Bosch

Bosch monopolizes the transmission steel belt of CVT gearbox? It may be incredible to think about it. It seems that most CVT gearboxes are used by Japanese car companies. How can a company from Germany monopolize the core components in CVT gearboxes? In fact, this only shows that Bosch’s management has a long-term vision, and completed the right to hold the patent of transmission steel belt technology through acquisition a long time ago. Therefore, if you want to manufacture CVT gearboxes at present, you have to buy them from Bosch. Because of the output of the gearbox, Bosch may not sell it, and even if it is sold, the cost will never be very low, so this is the first problem that needs to be faced in manufacturing CVT gearboxes.

Secondly, China brand only has the experience of developing and manufacturing CVT gearboxes at present, while other brands are blank in this field. Moreover, the technical system of CVT gearbox is very huge, so it is undoubtedly very difficult for a company with no relevant experience to develop CVT gearbox from scratch. Therefore, from the national level, it is difficult to achieve the ultimate goal of "overtaking in corners" by advocating the development of CVT gearbox.

◆ AT gearbox

The technology of AT gearbox is very mATure at present. In addition to many cars developing and manufacturing AT gearboxes themselves, there are also some companies specializing in gearbox production that also provide AT gearboxes with high technical content and more gears for manufacturers. Among these manufacturers, ZF from Germany and Aisin from Japan should be the most famous.

AT present, the AT gearbox technology of gearbox companies such as ZF and Aisin is very advanced, which can attract and wait for giants to buy their products. On the other hand, AT gearbox is difficult to balance transmission efficiency and smoothness, which requires rich experience in design and manufacturing. Therefore, it is difficult for the traditional AT gearbox to achieve the level of the current mainstream manufacturers from scratch, and it is even more difficult to achieve the goal of "overtaking in corners".

◆ dualclutchtransmission

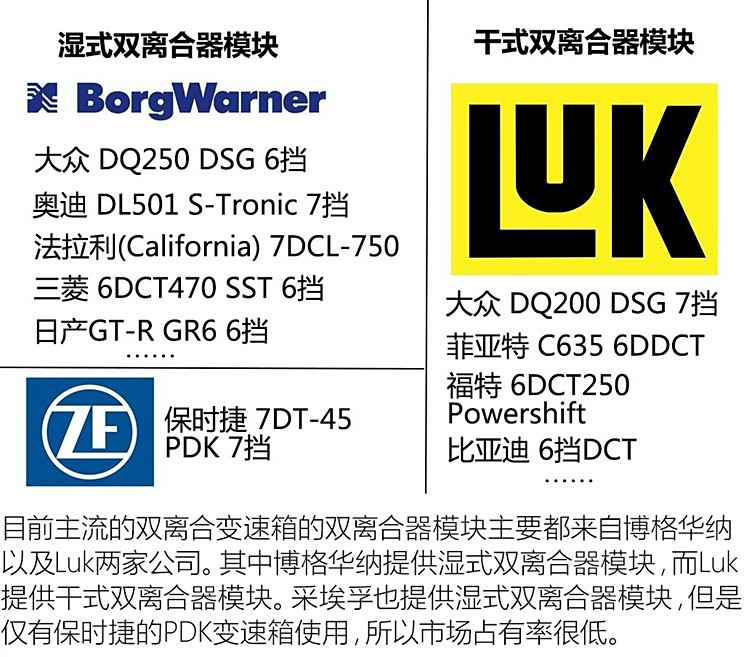

Compared with continuously variable transmission and automatic transmission, dual clutch transmission is more likely to achieve the purpose of "overtaking in corners", although in the field of dual clutch transmission, there is also a monopoly similar to Bosch’s to CVT: LuK (the developer of Schaeffler) in the field of actuator module and Borg Warner in the field of actuator module.

However, on the whole, there are still many possibilities in the field of dual-clutch gearbox. Except for the clutch module, it is difficult to shake the position of Luk and Borgwarner, there are many variables in other aspects, which gives China brand certain opportunities. Because Borgwarner, which has a strong voice in the industry by virtue of technical monopoly, also hopes to gain market recognition by promoting the development of dual-clutch gearbox in the domestic market, thus stabilizing its position in the field of wet dual-clutch modules, just like Bosch is to CVT. This is also the reason why Zhongfalian Investment Co., Ltd. will cooperate with Borg Warner to set up a joint venture company, but instead of developing a dual-clutch gearbox, it only produces wet dual-clutch modules.

However, as the investors of China Development Alliance, these nine China brands have achieved the task of research and development and production of dual-clutch gearboxes through different paths. For example, the car is developed by itself by purchasing dual-clutch modules from Borgwarner, while Borgwarner does not participate in the matching and adjustment of gearboxes, which are all done by JAC itself. Dongfeng, on the other hand, has changed a way to achieve the goal of having a dual-clutch gearbox by setting up a subsidiary with a foreign transmission company.

● Why Gertrak?

Compared with gearbox companies such as ZF and Aisin, Getrag’s popularity is not high, but its low popularity does not mean that its technology is not advanced enough or its strength is not strong enough. This German company, founded in 1935, is currently the largest gearbox manufacturer for commercial vehicles in the world. In January this year, Magna, an auto parts giant from Canada, completed the acquisition of Gertrak, and since then Gertrak has become a subsidiary of Magna.

However, at present, most of the Gertrak gearboxes used by China brands in China are products from Gertrak, a joint venture company between Gertrak and automobile, Jiangxi Province. The internal code is 6DCT250, which is a dry dual-clutch gearbox. Today, we disassemble a wet dual-clutch gearbox with the internal code of 6DCT150 produced by Oriental Trak Company.

关于作者